Project

Gigawatt scale renewable-based hydrogen value chain

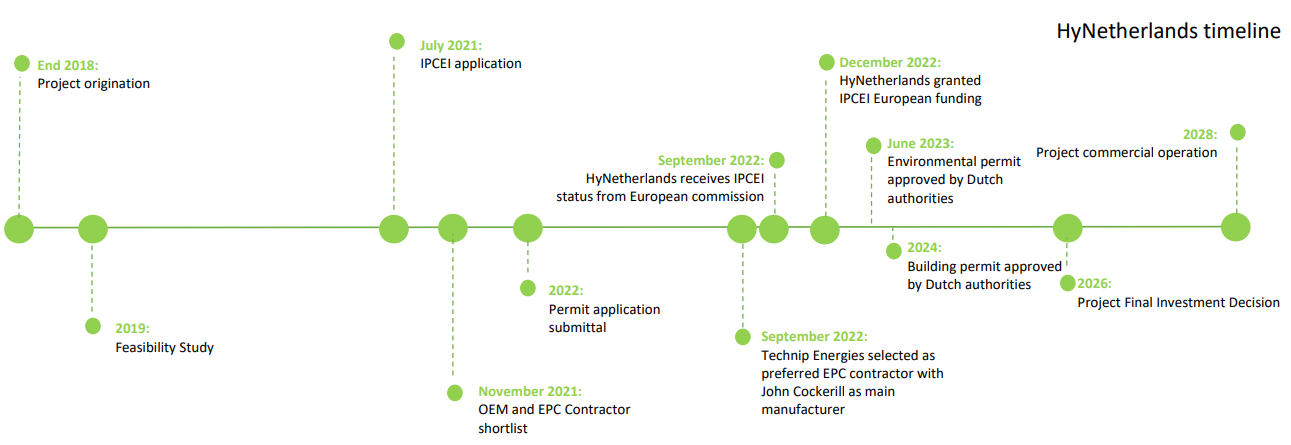

HyNetherlands aims to develop, build, and operate one of the first large-scale industrial value chains in Europe for the production and delivery of renewable-based hydrogen in the Northern Netherlands (Province of Groningen).

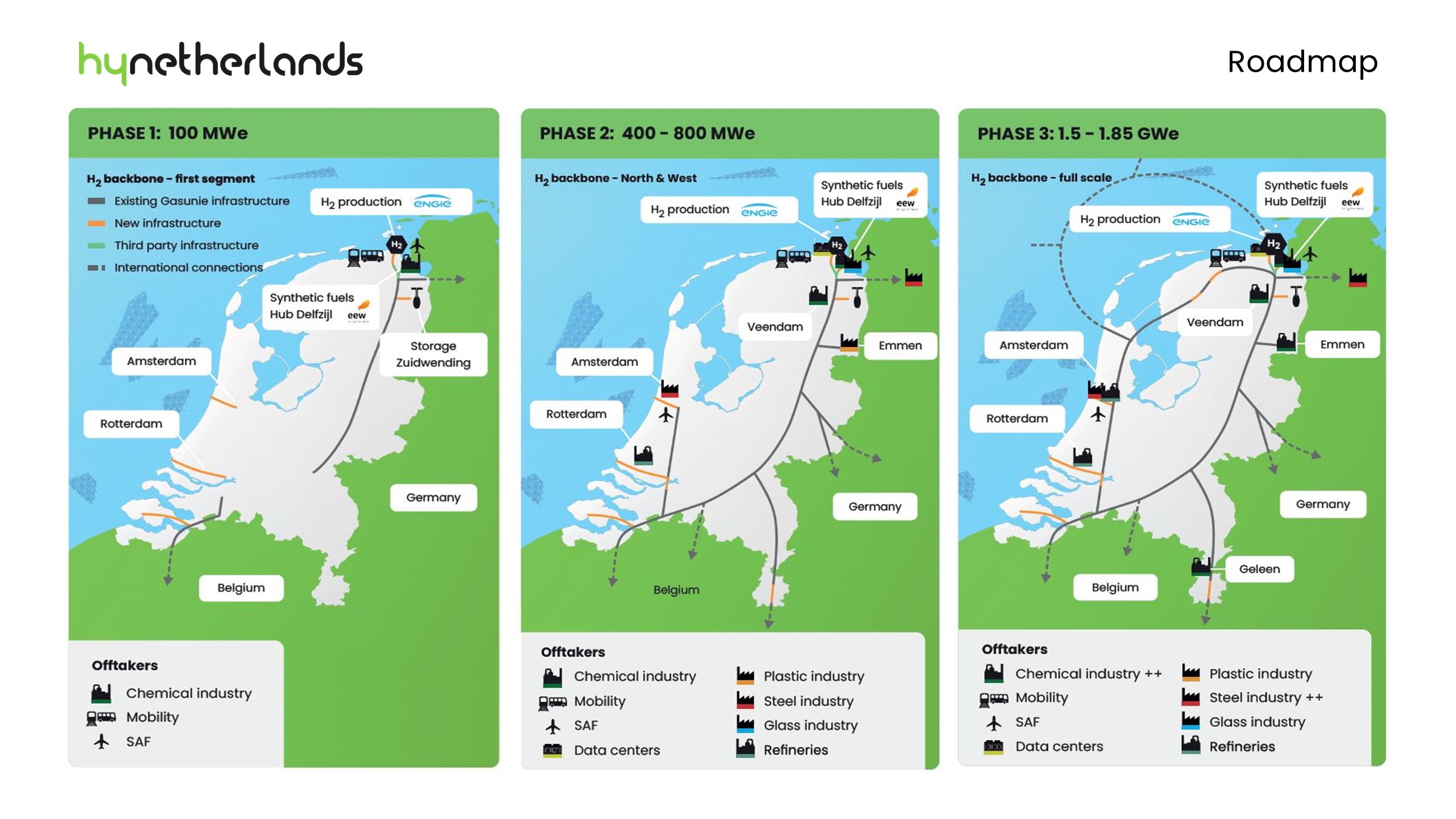

The long-term ambition of HyNetherlands is to increase its contribution to the decarbonization of industry and mobility in the Northern Netherlands and beyond. This ambition will be reached by gradually scaling-up the production capacity of the electrolyzers from 100MW in 2028 to 1.85GW after 2035. The project and its corresponding roadmap have all characteristics to lay the basis for Europe’s energy security of supply and energy sovereignty through a full decarbonized value chain, while ensuring future sound sector coupling and electrical and gas grid integration.

HyNetherlands will trigger:

- The market and commercialization of new renewable products in the transport sector

- The avoidance of 140 kilo tons per year of CO₂ starting from 2028

- The circularity of biogenic CO₂ from non-recyclable waste as well as circularity of oxygen

- The overall efficiency improvement of water electrolysis process against current standards

- The project will set the basis for a hydrogen backbone, which will spread out at both national and European level

Energy transition for industry and transport

HyNetherlands is uniquely positioned in Europe in the Northern Netherlands, where the natural gas economy is shifting towards a hydrogen economy.

This coastal region offers abundant offshore wind energy. There is an infrastructure in place focusing on re-utilization and currently the so called hydrogen backbone is at an advanced stage; an extensive network of hydrogen pipelines throughout the Netherlands and beyond. Part of the infrastructure is a large underground storage facility. HyNetherlands will create new jobs and will reorient qualified local gas staff towards hydrogen skills and techniques.

HyNetherlands accelerates the commercialization of an affordable energy carrier premium product through renewable based hydrogen on the emerging market, through an investment subsidized up to 75%. This will position European industry and investors on a scalable industrial project, taking the global lead in hydrogen production and commercialization.

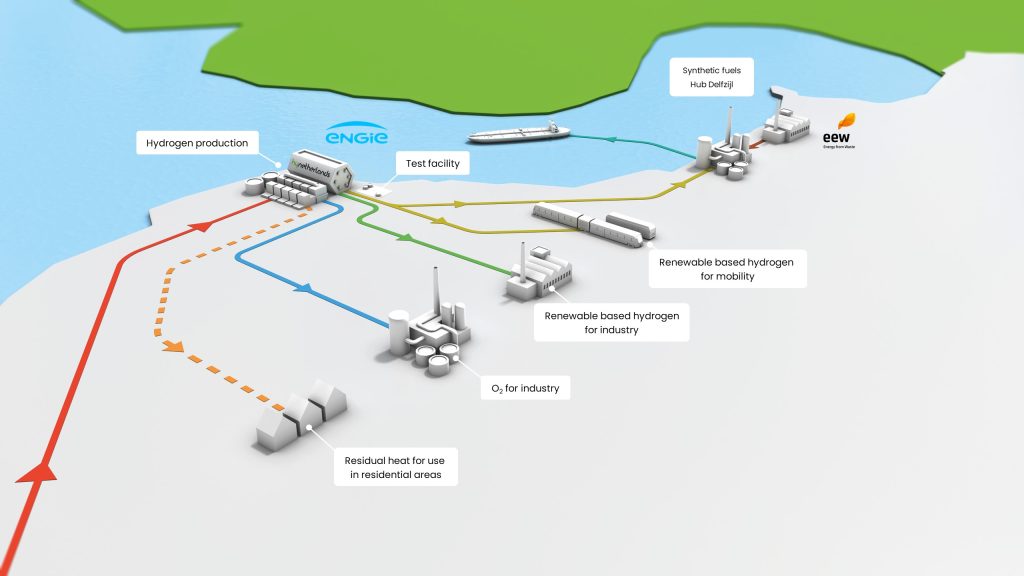

An industrial eco-system to enhance the future of energy

The ENGIE hydrogen production site will be located on the site of the Eems power plant in Eemshaven, 30 kilometers north-east of the city of Groningen and close to the German border. The renewable hydrogen can be supplied to tube trailers (for e.g. mobility) at the site and will be injected into the hydrogen backbone, based on the retrofitted existing gas network to be operated by HyNetwork Services, a subsidiary of Gasunie. The 100 MW electrolyzer, powered by 200 MW of wind capacity supplied by offshore wind turbines, will be able to follow the intermittent supply of electricity.

A major contribution to energy transition for hard-to-abate industrial sectors

For some industries with a high carbon footprint it is very hard to achieve CO₂ neutrality in the short term. European legislation being adopted (RED, Delegated Act) highlights the importance of a timely and integrated approach towards CO2 neutrality, which HyNetherlands project can heavily contribute to.

The advantage of this fully decarbonized value chain is that it reaches many aspects of the energy transition.

- From a climatic and environmental point of view with the avoidance of 140 kilotons per year of CO₂ from 2028.

- From an economic point of view for the Netherlands, by triggering new investments in offshore wind in the country, in the hydrogen infrastructure and by creating new jobs.

- In support to Europe’s sustainable energy sovereignty, by laying the foundations for Europe’s security of energy supply through a fully decarbonized value chain, while ensuring a healthy sectoral coupling in the future, as well as electricity and gas supply.

HyNL will be increasing production capacity from 100MW in 2028 to 1.85 GW after 2035.

HyNetherlands to transform industries and transport to reach carbon neutrality

- Trigger: HyNetherlands will initiate large-scale deployment of renewable hydrogen for a large spectrum of usages and will focus on those sectors ready to decarbonize by means of renewable hydrogen feedstock: chemical industry and synthetic fuels production but also hydrogen buses, trucks and trains.

- Replicability and expandibility: HyNetherlands roadmap is conceived to offer high replicability and bankability to further expand the business model

- Scalability: by leveraging on the derisked infrastructure, local economy can then grow to provide innovative energy solutions to a diversity of usage, from chemical sector to steel industry, at national then European level

The HyNetherlands project will directly contribute to both the Dutch (4 GW by 2030 of electrolyzer capacity) and the European Hydrogen roadmaps (40 GW by 2030).